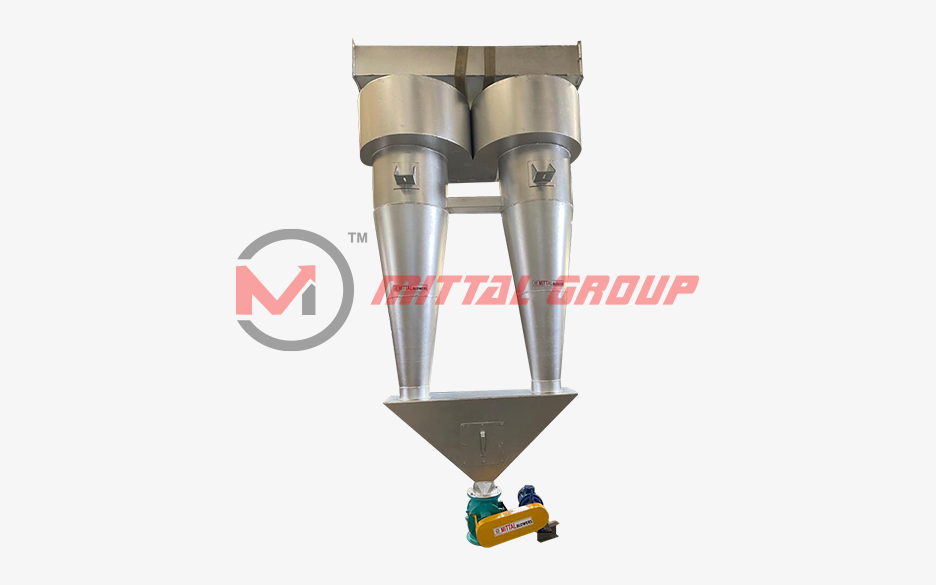

The multi-cyclone dust collection system represents the second generation of mechanical dust collectors following the cyclone. Within its chamber, it contains multiple parallel cyclonic tubes that effectively separate heavy dust particles from the air stream. This system serves as a primary separator to decrease the dust load on the bag filter or dust collector, and also functions as the primary spark trapper in certain scenarios.

Mittal Blowers has innovated various types of cyclonic tubes for different applications in the development of multi-cyclones. The cyclone tube is the central component of any multi-cyclone dust collector, with tube designs being tailored to specific applications.