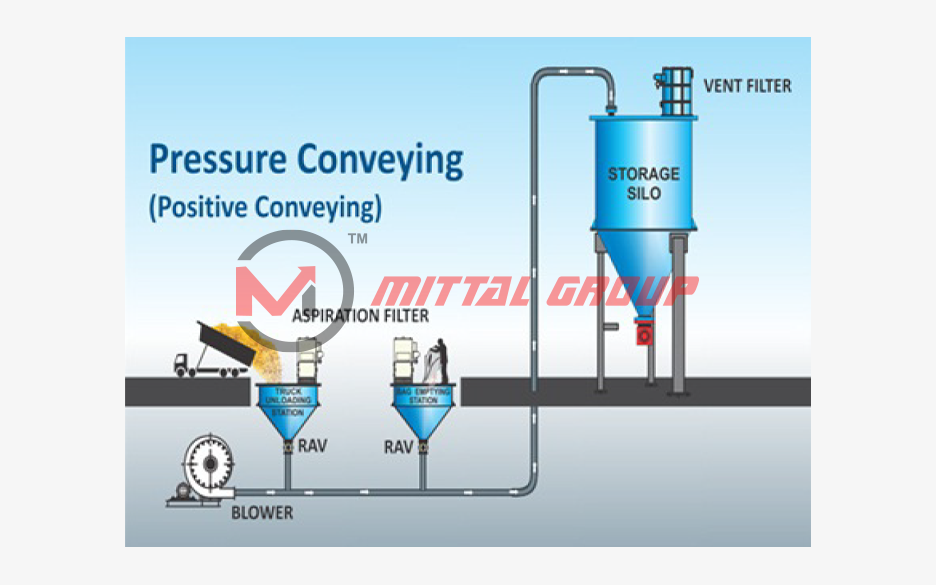

Pneumatic conveying systems are used to transport bulk materials such as powders or granules through a pipeline using air pressure. These systems are efficient, hygienic, and versatile, making them ideal for a wide range of industries including food processing, pharmaceuticals, and manufacturing.

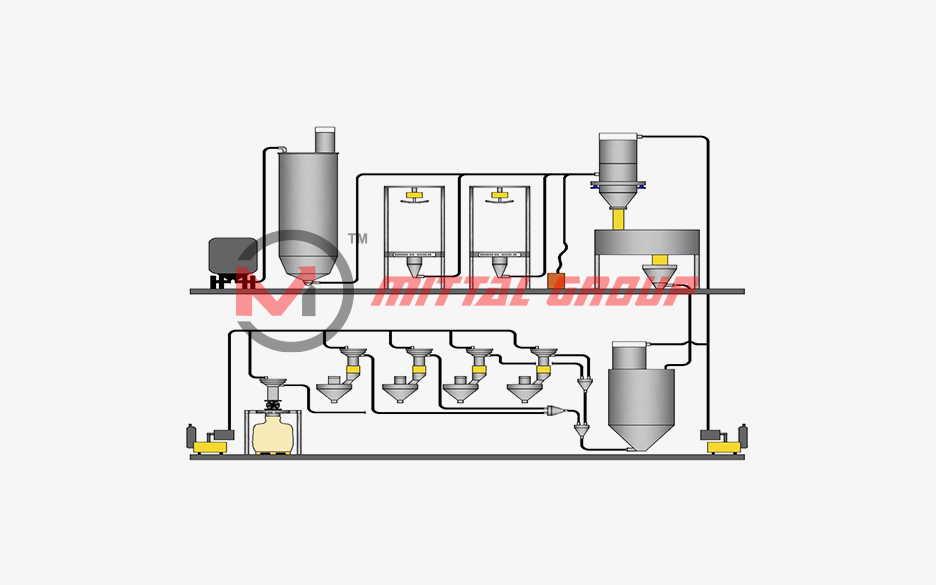

There are two main types of pneumatic conveying systems: dilute phase and dense phase. Dilute phase systems use high velocity air to transport materials in suspension through the pipeline, while dense phase systems use lower velocity air to move materials in a more controlled manner.